rotating bending machine for high cycle fatigue testing|rotating beam fatigue testing machine : tv shopping To provide full scale testing of the fatigue performance of our products, Apollo designed, built and commissioned the world’s first large scale rotating bending fatigue tester. Nicknamed the . WEB27 de ago. de 2022 · Nice x Olympique de Marseille Ligue 1 2022/23 (Campeonato Francês) 4ª rodada Data e horário: 28/08/2022, às 10h (de Brasília) Local: Allianz Riviera, Nice (FRA) Transmissão: Star+

{plog:ftitle_list}

webIPA. Pack de 24 74,90€. Ajouter au panier. DÉCOUVREZ PLUS DE BIÈRES. Découvrez l'art de la bière artisanale avec Blue Coast Brewery. Depuis notre brasserie de Nice, nous créons des bières primées.

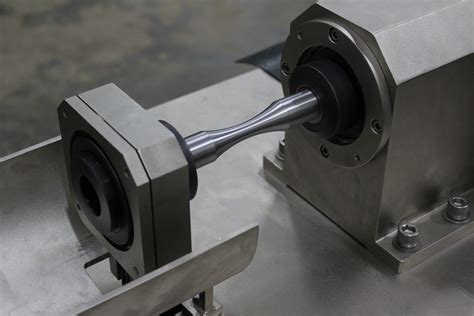

Features. Uses four-point beam loading condition to provide a consistent bending stress across the gauge section of the specimen. eP2 Controller for system control and cycle counting. Sample Break detection. Safety shield with interlock switch. Multiple collet sizes available depending .Fatigue testing allows manufacturers and researchers to get a critical understanding of how a material or component will perform in real-world loading scenarios over the course of time. .To provide full scale testing of the fatigue performance of our products, Apollo designed, built and commissioned the world’s first large scale rotating bending fatigue tester. Nicknamed the .ADMET fatigue testing machines provide accurate and reliable results for evaluating the endurance and durability of materials. Contact us to learn more. . and High Cycle Fatigue (HCF) tests a possibility up to the 15Hz range. .

w+b Materials Testing Systems Closed-Loop Controlled Rotary Bending Fatigue Testing Machines Series UBM with Load Cell instead of Dead-Weights The full line of rotary bending testing machines is also available with incorporated Force Transducer with digital closed loop force control and application software. In this case is the rotary bending machine is equipped .About the Rotating Beam Fatigue Tester (RBFT) Rotating beam fatigue testing machine facilitates testing of materials for the generation of S-N curve from which endurance limit can be determined. Load is applied using dead .

This study develops an experimental methodology for evaluation of high-cycle tooth bending fatigue lives of gears under both loading conditions. Unique specimens for tooth bending fatigue and an adaptive diagnostics method for test termination are designed while root strains under high-speed conditions are quantified. Ueki [] in his paper on high-speed bending fatigue testing of composite materials (2018) devised and evaluated a methodology for fatigue testing of fiber reinforced composites.In this experiment, specimen was held as a cantilever and given a periodic stress at a frequency of 230 Hz. The specimen was kept at a room temperature by external cooling since the rise in .important in testing certain alloys that heat up The R. R. Moore, recognized as the standard for rotating beam fatigue testing, has been serving industry faithfully for more than 7O years. Over that time, the R. R. Moore has demonstrated an unsurpassed quality of machine design. The use of the rugged cast aluminum machine frame and heavy duty .Westmoreland Mechanical Testing & Research (WMT&R) provides customizable, high-volume, and extensive scope high cycle fatigue (HCF) testing which can determine fatigue strength of a particular material through a variety of applications including aerospace, automotive, power generation and oil and gas industries – providing you with analytical results to understand your .

Fatigue lives of greater than 100,000 cycles are defined as High Cycle Fatigue. Axial high cycle fatigue testing at SMaRT is primarily conducted on Vibrophore test machines, which use magnetic resonance to deliver low amplitude, high frequency (usually in the range of 80-100Hz dependant on specimen geometry and material stiffness) testing .This paper presents the design and development of a fast rotating bending test machine for high-cycle fatigue tests, which can rotate up to 18,000 rpm, generating cyclic stresses at 300 Hz. The bending force is applied by an electric actuator, connected in series with a load cell.This aims at designing and constructing a rotating bending fatigue testing machine that is capable of testing the fatigue life of various samples of specimen of different minimum diameters and subjected to loads varying from 30Kg to 90 Kg etc. Also with the result of each test carried out with this machine, the numbers of cycles required to .Rotating Fatigue Machine SM1090V A benchtop machine for demonstrating the failure of materials when subjected to an alternating stress, showing both low and high cycle fatigue. Materials Testing and Properties. TecQuipment Ltd, .

This paper presents the design and development of a fast rotating bending test machine for high-cycle fatigue tests, which can rotate up to 18,000 rpm, generating cyclic stresses at 300 Hz. The bending force is applied by an electric actuator, connected in series with a load cell. An Arduino board with a DC motor controller shield receives the force feedback from the load cell, .

rotating bending fatigue testing machine

rotating beam fatigue testing system

with reduced gage section (i.e. hourglass specimen) for rotating bending fatigue test, were designed according to ASTM Standard E-466 [ 13] and ISO 1143 [14], respectively. The specimen . In high cycle fatigue regime, the majority of the fatigue life is dominated by crack initiation stage. Since the cracks mainly initiateTo provide full scale testing of the fatigue performance of our products, Apollo designed, built and commissioned the world’s first large scale rotating bending fatigue tester. Nicknamed the Rotatamatron 3000, the machine is capable of applying a constant stress across a 2.75 in (70 mm) diameter reduced section with a maximum load of 50,000 lbs.

This paper presents the design and development of a fast rotating bending test machine for high-cycle fatigue tests, which can rotate up to 18,000 rpm, generating cyclic stresses at 300 Hz. The .

A rotating bending fatigue testing machine was developed by keeping in mind the basic concepts of technical theory of bending of elastic beams. . The high cycle fatigue S-N curves of small . Fatigue tests were performed in rotating bending by means of a dual-spindle rotating bending fatigue testing machine [5, 6] in the room atmosphere without any control of temperature and humidity .To meet test needs of various applications, Fatigue Dynamics offers rotating beam test machines in bending moment capacities ranging from 60 in.-lb. to 1500 in.-lb. Optional accessories include a high temperature furnace (up to 1800°F), furnace temperature controller, and corrosion chamber.

Rotating Beam Fatigue and Axial Fatigue Test Methods. The main difference between the two test methods is that axial fatigue testing applies uniform stress throughout the cross-section of the specimen under test, whereas rotating beam fatigue testing creates an applied stress that increases linearly from 0 at the neutral axis to a maximum stress value at the specimen surface.RR Moore Rotating Bending Fatigue Testing Machine – ISO1143 . Controller including cycle counter Integrated variable speed control provides the RR Moore Fatigue Testing Systems’ capability to operate at speeds from 500 RPM to 10.000 RPM. Speed control is important in testing certain materials that heat up when highly stressed, and it .Fatigue Testing Materials Testing to obtain S-Nf Curves is common; several ASTM standards address stress-based fatigue testing. The "Rotating Bending Testing Machine" is similar to the original railroad axle-type Wohler used where the bending moment is constant along the beam length. Each point on the Surface of the Rotating

In the present investigation the high cycle fatigue behavior of Al6061-T6 aluminum alloy has been investigated at different frequencies. Fatigue tests were conducted at a frequency of 33 Hz and 50 Hz. A constant amplitude rotating bending fatigue experiment was performed at room temperature at a stress ratio of −1. 18. ROTATING BENDING TESTING MACHINE The type of S-N curve created by this machine is identified as a rotating-bending, stress-controlled fatigue data curve. The rotating bending test machine is used to create an S-N curve by turning the motor at a constant revolution per minutes, or frequency.A rotating-bending testing machine is comprised mainly of a motor to rotate the wire and a constraint to maintain the strain amplitude. Rotating-bending fatigue testing has become a common test setup for the structural fatigue evaluation of Nitinol wires . [80] studied the high-cycle fatigue prediction using Crossland and Dang Van criteria .

These applications include high-cycle fatigue, low-cycle fatigue, thermo-mechanical fatigue, fracture mechanics, crack propagation and growth studies, fracture toughness, bi-axial, axial-torsional, multi-axial, high strain rate, quasi-static, creep, stress-relaxation, and other types of dynamic and static tests.The American Society for Testing and Materials defines fatigue life, . for seven metal alloys. Curves were generated using rotating–bending and reversed-cycle tests. Source: William D. Callister, David G. Rethwisch. Materials Science and Engineering: An Introduction 9th Edition, Wiley; 9 edition (December 4, 2013), ISBN-13: 978-1118324578 . The eXpert 9300 series Rotating Beam Fatigue Test Systems feature a dual spindle system design exerting uniform bending stress across the entire test specimen. Capable of performing rotating beam fatigue at speeds up 6,000 rpm (100Hz) and bending moments up to 50Nm (36.8 lb-ft), the eXpert 9300 Rotating Beam Fatigue Testing Machines can .

rotating beam fatigue testing machine

thickness measurement equipment

21 de jan. de 2023 · LOTOFACIL REDUÇAO DE 22 PARA 19 EM APENAS 6 JOGOS PLANILHA GRATIS. Aprenda com essas dicas como ganhar nas loterias utilizando a técnica de Fechamento. O .

rotating bending machine for high cycle fatigue testing|rotating beam fatigue testing machine